…from scientists to scientists

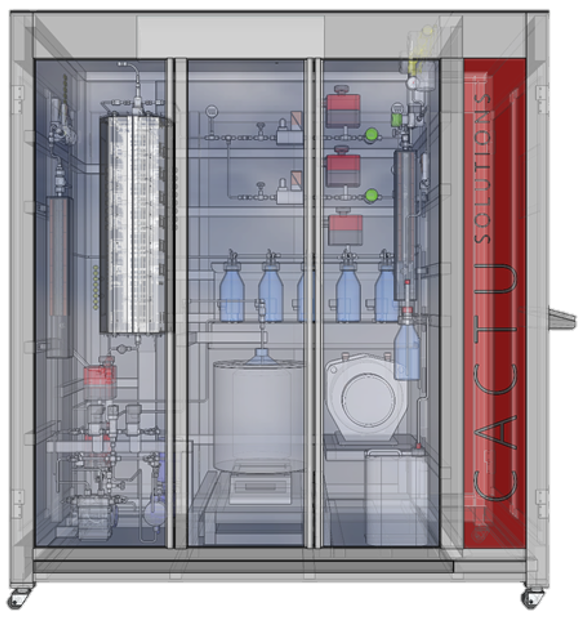

Welcome to CACTU Solutions, the provider of state-of-the-art solutions in operating, designing, and building fixed-bed catalytic testing units. With over 30 years of experiences, we have a proven track record of delivering high-quality services to clients around the world. Our team of seasoned experts is highly skilled in the latest technological advancements, ensuring that we provide innovative and customized solutions tailored to your unique requirements. As a company founded at the University of Chemistry and Technology, Prague, we are committed to upholding the highest standards of quality, reliability, and professionalism. Choose CACTU Solutions today to experience the best in fixed-bed catalytic testing units.

- The best tool for the lab testing of catalysts activity

- Hydrogenation, hydrocracking, oxidation and many others

- Pressures up to 200 bar, temperatures up to 600 °C

- Wide range of processed feedstocks

- Solid feedstocks with the melting point up to 140 °C

- Automatization of the process via remote control

- Automatic products sampling

- One or two-reactor design for the perfect variability

- Different volumes of tube reactors included (30 – 300 ml)

- Online GC-FID/TCD connection for off-gas composition measurement

Our benefits

Our references

Our units were used in many industrial applications and research works.

- Hydrocracking of Fischer-Tropsch wax for Orlen Unipetrol refinery

- Hydrotreating of HTL oils for Crossbridge Energy Fredericia

- Hydrotreating of HTL and pyrolysis oils for BayernOil Raffineriegesellschaft mbH

- Hydrogenation of durene-based feedstock for Ranido (Prague)

- Straka, P., Auersvald, M., Vrtiška, D., Kittel, H., Šimáček, P., & Vozka, P. (2023). Production of transportation fuels via hydrotreating of scrap tires pyrolysis oil. Chemical Engineering Journal, 141764.

- dos Passos, J. S., Straka, P., Auersvald, M., & Biller, P. (2023). Upgrading of hydrothermal liquefaction biocrudes from mono-and co-liquefaction of cow manure and wheat straw through hydrotreating and distillation. Chemical Engineering Journal, 452, 139636.

- Kittel, H., Straka, P., Šimáček, P., & Kadleček, D. (2022). Kerosene from hydrocracking for JET fuel with reduced aromatic content. Petroleum Science and Technology, 1-17.

- Shumeiko, B., Auersvald, M., Straka, P., Šimáček, P., Vrtiška, D., & Kubička, D. (2020). Efficient one-stage bio-oil upgrading over sulfided catalysts. ACS Sustainable Chemistry & Engineering, 8(40), 15149-15167

- Váchová, V., Toullis, D., Straka, P., Šimáček, P., Staš, M., Gdovin, A., Beňo, Z. & Blažek, J. (2020). Composition and Properties of Rapeseed Oil Hydrotreating Products over CoMo/Al2O3 and NiMo/Al2O3 Catalysts. Energy & Fuels, 34(8), 9609-9619.

- Straka, P., Blažek, J., Toullis, D., Ihnát, T. & Šimáček, P. (2021). The Effect of the Reaction Conditions on the Properties of Products from Co-hydrotreating of Rapeseed oil and Petroleum Middle Distillates. Catalysts, 11(4), 442.

- Blažek, J., Toullis, D., Straka, P., Staš, M. & Šimáček, P. (2021). Influence of Pressure on Product Composition and Hydrogen Consumption in Hydrotreating of Gas Oil and Rapeseed Oil Blends over a NiMo Catalysts. Catalysts, 11(9), 1093.

- Tomášek, J., Matějovský, L., Lamblová, M. & Blažek, J. (2020). Properties and composition of products from hydrotreating of straight-run gas oil and its mixtures with light cycle oil over sulfidic Ni-Mo/Al2O3 catalyst. ACS Omega, 5(43), 27922-27932.